compressed air purity testing|validation of compressed air : supplier Learn how to sample and test compressed air for particles, water, and oil according to ISO 8573 standards. Compare different methods, such as laser particle counter, filter collection, and microscopy, and their .

Resultado da 30 de jan. de 2024 · Após dez meses de investigações, a Polícia Federal (PF) de São Paulo concluiu neste mês o inquérito contra o influenciador fitness Renato Cariani por suspeita de desvio de produtos .

{plog:ftitle_list}

6 de nov. de 2023 · Nuveen is a leading sponsor of closed-end funds (CEFs) with $51 billion of assets under management across 48 CEFs as of 30 Sep 2023. The funds offer exposure to a broad range of asset classes and .

Learn about the sources, types and effects of contamination in compressed air systems and the international standards for testing and purifying compressed air. This document provides an .Trace Analytics offers compressed air testing services to ISO 8573 standards for various industries. Learn about the contaminants, methods, and kits for testing compressed air purity .ISO 8573-1:2010 specifies purity classes of compressed air with respect to particles, water and oil independent of the location in the compressed air system at which the air is specified or .

Learn how to test compressed air quality according to ISO 8573 standards and detect impurities such as water, solid particles, and oil. Find out why compressed air testing .Compressed air purity is essential to many manufacturing, food processing, bottling and packaging operations. Testing includes direct & indirect product contact, USP, the European Pharmacopeia, or ISO 8573, ISO 14664 standards. Learn how to sample and test compressed air for particles, water, and oil according to ISO 8573 standards. Compare different methods, such as laser particle counter, filter collection, and microscopy, and their .

This part of ISO 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed air system at which the air is specified .Trace Analytics is an A2LA accredited laboratory that provides compressed air and gas testing solutions for various industries and applications. It offers easy to use sampling kits, rapid .

A thorough understanding of compressed air quality and testing is indispensable when designing your system to achieve the purity levels your application requires. The International .Trace Analytics has designed the AirCheck Kit models K810. and K802 to meet the demand for compressed air and gas purity testing in the manufacturing sectors. Clean, dry, and oil-free air is necessity to avoid contamination in the manufacture of food, drugs, and equipment used in critical processes. Sample collection and analytical methods are .ISO 8573-4,Compressed air — Part 4: Test methods for solid particle content . ISO 8573-5, Compressed air — Part 5: Determination of oil vapour and organic solvent content. . the compressed air purity. NOTE Measurements should be carried out at the actual operating conditions as otherwise the balance between impurities in liq-

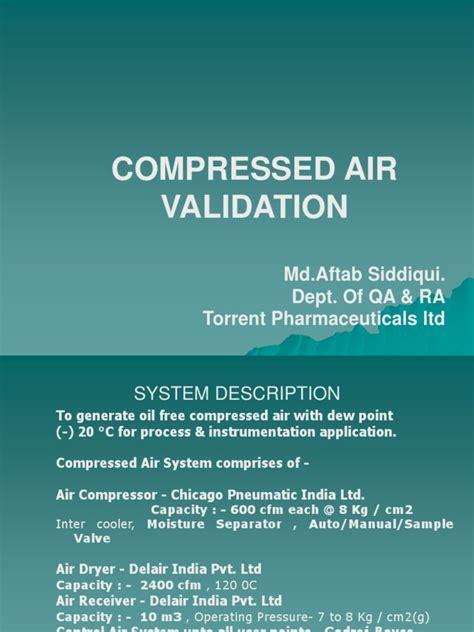

validation of compressed air

ISO 8573-1:2010 provides general information about contaminants in compressed-air systems as well as links to the other parts of ISO 8573, either for the measurement of compressed air purity or the specification of compressed-air purity requirements. The ISO 8537 compressed air standard is an internationally recognized system that applies to the purity of compressed air in an industrial setting. This testing protocol is both an efficient and cost-effective method of determining the level of .ISO 7183, Compressed-air dryers — Specification and testing; ISO 8573-2, Compressed air — Part 2: Test methods for oil aerosol content; ISO 8573-3, Compressed air — Part 3: Test methods for measurement of humidity; ISO 8573-4, Compressed air — Part 4: Test methods for solid particle content; ISO 8573-5, Compressed air — Part 5: Test methods for oil vapour and .ISO 8573 Testing ISO 8573 is an internationally recognised standard that defines major contaminants in compressed air and presents a comprehensive system for air purity designations. The implementation of this standard supports accurate testing of the major contaminants in compressed air – particles, water, oil, and microorganisms.

to specify the purity of compressed air required at a particular point in a compressed air system iso8573-1:2010 to test a compressed air system for one or more specific contaminants iso8573 parts 2 to 9 to verify the performance of compressed air purification equpment filters - iso12500 series dryers - iso7183 to benchmark the performance of .to test their compressed air system and classify it in accordance with ISO 8573-1, then the test methods and equipment shown in ISO 8573 parts 2 to 9 must be used. ISO 8573-1 is commonly used to specify compressed air purity (quality), however it is not used correctly when it comes to the testing of compressed air

to test their compressed air system and classify it in accordance with ISO 8573-1, then the test methods and equipment shown in ISO 8573 parts 2 to 9 must be used. ISO 8573-1 is commonly used to specify compressed air purity (quality), however it is not used correctly when it comes to the testing of compressed air

The standard also determines that air quality shall be designated by the following nomenclature: Compressed Air Purity Classes A, B, C:Where:A= solid particle class designationB= humidity and liquid water class designationC= oil class designationMore than you thought . reliable source of compressed air. Testing conditions shall be controlled . The right compressed air purity is key to safeguarding production integrity and efficiency. Here is a guide on using ISO 8573-1:2010 to achieve the proper air quality. Need to understand iso classes for compressed air quality?Compressed Air Testing As a dedicated provider of compressed air testing solutions, our accredited laboratory specializes in analyzing compressed air and gas for a wide range of industries, including manufacturing and medical facilities. Contact us ISO 8573 The ISO 8573 Purity Class chosen for a manufacturing facility depends on its specific use of compressed air.

We provide international standards and methods for sampling and the testing of compressed air, ambient air and pure gas delivery systems. This includes a multitude of pure gas types up to Five 9’s purity. Additionally, we collect mold & bacteria samples for testing in compressed, ambient, and pure gasses.The test system ensures reliable testing of breathing air according to the applicable classification, EN 12021. Pollutant detection and measurement Using the Dräger Aerotest Alpha, it is possible to reliably determine different potential pollutants such as carbon monoxide, carbon dioxide, hydro steam or oil in the compressed air flow.

There are various compressed air quality and purity testing instruments available, including PID sensors, laser particle counters and dew-point sensors, which measure crucial aspects such as humidity, oil content and particle count. Designed to provide accurate and reliable measurements, the compressed air quality testing equipment ensures the .A.4.5 Compressed air for breathing apparatus from EN529 A.4.5 Compressed air for breathing apparatus (EN12021) A.4.5.1 General A compressor system will have produced the compressed air supplied to a breathing apparatus. The compressor system may be used for filling individual high-pressure pressure vessels or those on a

compressed air testing procedure

In addition, it is to be used to assess compressed air purity such that the purity class can be stated in accordance with ISO 8573-1 for particles of Class 1, 2, 3, . NOTE 1 The test methods described in this document are those suitable for determining the purity classes given in . It contains small hydrocarbons, CO, CO2, SO2, and NOX. Oil mainly comes from inside an oil-flooded air compressor. As the air passes through the compressor, it will pick up remnants of oil aerosols and carry it downstream. With high temperatures inside the air compressor, some of the oil will vaporize.‘On the spot’ compressed air quality testing, providing accurate indication of contamination levels both upstream and downstream of purification equipment. . Coatings and Encapsulants Aerospace Systems and Technologies Air Preparation (FRL) and Dryers Bioprocessing and Medical Technologies Cylinders and Actuators EMI Shielding Filters, .Our latest Air Purity Analyser to be released is our APA MK3 which incorporates Electronic Sensors for CO, CO2 and H2O measurement which is a cost saving for our clients. . Safewell sell the microbiological impaction sampler to test the quality of compressed air and gases used in cleanrooms and pharmaceutical environments. View product .

TRI Air Testing is ISO 17025:2017 accredited by AIHA-LAP, LLC, compliant to ANSI/ISO/ASQ 9001:2015, and participates in a compressed air quality proficiency program. The accreditation and proficiencies ensure our lab meets the highest standards of quality and can deliver reliable,consistent laboratory test results.The International Organization for Standardization (ISO) is the world’s largest developer of voluntary International Standards. It is a network of national standards bodies. These national standards bodies make up the ISO membership. It is an independent, non-governmental organization made up of members from 164 countries. The ISO 8573-1 specification is used by .The ISO 8573 standard specifies the purity of compressed air. Compressed air is utilized across many industries, including medical, pharmaceutical, and food. Particulate matter contamination of compressed air and its measurement is addressed by ISO 8573:4. The methods described in ISO 8573:4 are appropriate for oil, water, and solid particulate. ISO 8573 .

Uncover the secrets of maintaining compressed air purity levels with ISO 8573-1:2010. Don't let contaminants compromise your productivity and profitability. . ISO 8573-1:2010 is the international standard used by compressor and filter manufacturers and testing laboratories and is applied across manufacturing facilities to ensure high-quality .IMPORTANCE OF COMPRESSED AIR QUALITY TESTING AND ISO 8573-1 REQUIREMENTS. In modern compressed air systems, . ISO 8573-1 is an international standard that specifies the purity of compressed air with respect to three main contaminants: particles, water and oil. These contaminants are classified into different purity classes based on their .Part 1: Contaminants and purity classes; ISO 8573-5, Compressed air ? Part 5: Test methods for oil vapour and organic solvent content; ISO 12500-1, Filters for compressed air ? Test methods ? Part 1: Oil aerosols; DIN 32645, Chemical analysis ? Decision limit, detection limit and determination limit under repeatability conditions - Terms .Testing can include gas purity by difference e.g. the pure gas concentration is determined to ± 0.3% absolute, then all other determined gases are subtracted from 100.00% to arrive at the reported value. . We’ve been testing compressed air and gases for over 30 yers. We have a Team of Experts ready to answer your questions and help you get .

tests for meniscal tear knee

tfcc tear special test

Siga os placares ao vivo para São Bernardo e outros resultados de futebol agora em Flashscore.com.br! Confira os resultados da Supercopa do Brasil 2024 ao vivo em Flashscore.com.br: 04.02. Palmeiras x São Paulo incluindo prévias, estatísticas de confronto direto (H2H), placares ao vivo e relatórios de partida da Supercopa do Brasil!

compressed air purity testing|validation of compressed air